Outdoor Usage and First-Class Grade Printed Film Faced Plywood

Basic Info

Model No.: 1220mmx2440mm

Product Description

Model NO.: 1220mmx2440mm Grain: Black or Brown Color Bonding Strength: Ⅱ(Ns) Formaldehyde Emission Standards: E1 Place of Origins: China Usage: Outdoor Core: Poplar, Combi, Hardwood etc. Thickness: 9-21mm Number of Plies: From 9 to 13 Plies According to Thickness and Cust Certificate: ISO, Fsc, SGS MOQ: 1X40hq Specification: CE, FSC, SGS, ISO9001 HS Code: 4412390090 Material: Poplar Core Polywood: Poplar Board Plywood Type: 13-Ply Specifications: 1220*2440*18mm Grade: Grade One Size: 1220*2440mm, 1250*2500mm Glue: WBP, Mr, Melamine Surface Type: Smooth, Anti-Slip Market: Middle East, Southeast Asia, South America, etc Color of Surface: Black, Brown or as Customers′ Request Trademark: GOLDLUCK Origin: Shandong outdoor usage and First-Class Grade printed Film Faced Plywood

(1)Size

1220 X 2440mm, 1250 X 2500mm or as requested

(2)Thickness

Different thickness available, from 9mm to 21mm

(3)Core

Poplar, birch, hardwood, combined or requested by clients

(4)Glue: WBP, MR

Film faced PLYWOOD In construction, Film Faced Plywood/ Waterproof Plywood is a special treated plywood that is quoted and designed to resist rotting in a high-moisture concrete environment.

Marine Plywood is frequently used in the construction; Sub Frames, docks, and boats due to the durability, strength, and resistance to wrapping.

Precautions

1) It should be no long time soaked and sun exposure, keep flat in dry and well-ventilated place.

2) Sealing of edges or holes: Film faced plywood edges or holes are fully sealed with water proof phenolic paint for three times, to obtain full value, any recut edges should sealed as soon as possible with water proof phenolic paint.

3) Usage: The wood columns(specification: 5X10cm or 10X10cm) touching templates shall be placed longitudinally. Keep level between templates, if there are the joints between them, use putty or adhesive tape to flatten and seal; Joints shall not be grout leaking. Templates should avoid touching hard thing to get damaged.

4) Clearing: To obtain full life, cleaning should be carried out immediately after each use. The surface should be wiped with release agent.

WELCOME TO LOOK THROUGH OUR PLYWOOD PRODUCTS.

THE MORE PRODUCTS, PLEASE VISIT OUR WEBSITE: www.qdgoldluck.com.

Contact person: Lydia

Mobile: 86-15066267015

Contact us if you need more details on Printed Film Faced Plywood. We are ready to answer your questions on packaging, logistics, certification or any other aspects about First-Class Grade Plywood、Outdoor Usage Plywood. If these products fail to match your need, please contact us and we would like to provide relevant information.

(1)Size

1220 X 2440mm, 1250 X 2500mm or as requested

(2)Thickness

Different thickness available, from 9mm to 21mm

(3)Core

Poplar, birch, hardwood, combined or requested by clients

(4)Glue: WBP, MR

Film faced PLYWOOD In construction, Film Faced Plywood/ Waterproof Plywood is a special treated plywood that is quoted and designed to resist rotting in a high-moisture concrete environment.

Marine Plywood is frequently used in the construction; Sub Frames, docks, and boats due to the durability, strength, and resistance to wrapping.

Precautions

1) It should be no long time soaked and sun exposure, keep flat in dry and well-ventilated place.

2) Sealing of edges or holes: Film faced plywood edges or holes are fully sealed with water proof phenolic paint for three times, to obtain full value, any recut edges should sealed as soon as possible with water proof phenolic paint.

3) Usage: The wood columns(specification: 5X10cm or 10X10cm) touching templates shall be placed longitudinally. Keep level between templates, if there are the joints between them, use putty or adhesive tape to flatten and seal; Joints shall not be grout leaking. Templates should avoid touching hard thing to get damaged.

4) Clearing: To obtain full life, cleaning should be carried out immediately after each use. The surface should be wiped with release agent.

WELCOME TO LOOK THROUGH OUR PLYWOOD PRODUCTS.

THE MORE PRODUCTS, PLEASE VISIT OUR WEBSITE: www.qdgoldluck.com.

Contact person: Lydia

Mobile: 86-15066267015

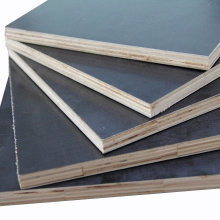

| Film faced shuttering plywood/marine plywood/concrete plywood/construction plywood | |

| size | 1220*2440mm,1250*2500mm |

| Core: | Poplar,hardwood,birch,combine |

| thickness | 9mm,12mm,15mm,18mm,20mm,21mm |

| film | Black film, domestic brown film, imported dynea brown film |

| Length(width) tolerance | +/-0.2mm |

| Thickness tolerance | +/-0.5mm |

| edge | Sealed with waterproof paint |

| glue | MR, WBP |

| moisture | 6-14% |

| packing | Standard exporting package( bottom is pallet, covered with plastic film, around is carton, strengthen by steel tape with 3*6 |

| Loading quantity | 56cbm/40HC |

| Minimum order quantity | 20/40 GP/HQ |

| usage | Used for construction, building house, flooring,shopping mall |

| Payment term | TT or L/C at sight |

| Delivery time | Within 15 days after get prepayment |

Product Categories : Film Faced Plywood

Premium Related Products

Other Products

Hot Products

Flower Color Paper Overlaid Plywood(Hote sale) Melamine Paper Overlaid Plywood with All DesignsFirerate HPL Plywood for Furniture, Cabinet and Interior DecorationHPL Plywood/HPL Plywood for Furniture(1220*2440) Factory Direct-Sale Plain Hardboard /HDF18mm Plain Particle Board / Plain Chipboard (QDGL20140321)Hot Sell Hardboard with Good Price (HB-28)18mm High Quality Blockboard (QDGL20140321)1220*2440*4.5mm Melamine Faced MDF Manufacturer16mm 18mm 25mm Okoume Faced Blockboard12mm Plain MDF Raw MDF (QDGL20140321)Fire Rate Chip Board /Particle Board (PARTICLE BOARD01)Okoume/Bintangor/Oak/Teak/Birch Commercial Plywood(Cheap Price, Good Quality) Film Faced Plywood/Shuttering Formwork Plywood/Marine PlywoodBrown Film Faced Plywood for BuildingPacking Grade China Cheap Price Commercial Plywood